They say necessity is the mother of invention and that certainly was the case this month at Ithaca College, where our friends in the Center for Print Production found themselves in the unique position of being able to produce PPE using the college’s print equipment and materials. Jeff Golden, director of general services at the college, reached out to EBP for help in ramping up production, and what happened next is a story of true partnership on many levels.

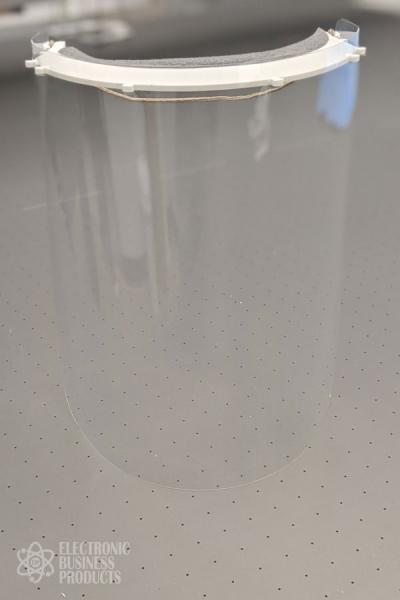

“When Jeff called to let me know they were using the Colex cutter we had sold them to make PPE, my first reaction was, ‘How can we help?’” said Paul Liguori, Vice President of Sales for EBP. Help, as it turned out, was needed in assembling the face shields to speed up the production line, so three EBP employees - Paul, Chris Liguori and Dan Swanson - traveled to the college and spent the day assembling hundreds of shields they then donated to local medical workers at Upstate Medical Center and Hearth Management.

The process, they found, was laborious and time-consuming but Golden’s crew was working with what they had. “There is a rotary tool accessory for the Colex unit that would allow us to greatly increase production,” Golden explained, “but with no budget for it in our current situation, we asked Paul if EBP could help.”

The request was a welcome one. “We’ve told Jeff, as we tell all customers, that we would be with him before, during and after the sale,” Liguori explained, “and this was no exception.” EBP was more than willing to do what we could to secure the part, but to fulfill this particular request we too would need to ask for help. “I made the call right away,” said Liguori. That call was to Ricoh, and the response was swift.

“We got together with EBP and in short time we were able to obtain the rotary cutter for Jeff at no additional cost to Ithaca College,” said Tom Koenig, District Business Manager for Ricoh USA. “We have a great relationship with EBP and we were honored to be able to contribute to their efforts to support such a great cause.”

By the end of the week, the requested rotary tool had been secured, shipped and installed in Ithaca’s print shop. The difference was immediate, and PPE production has already increased significantly. “Nearly a week of face mask production can now be done in a single day,” said Golden.

Good news for those needing to order PPE, but also for Golden’s team on a personal level. Just weeks ago, they were faced with the possibility of furlough. Today they’ve grown to a staff of seven. And with New York gearing up for a gradual reopening under a plan mandating masks for all public-interacting employees and a 90-day supply of PPE for hospitals, they’ll be busy. “We’re in a unique spot to help with this,” Golden said. “And we’re glad to do it.”

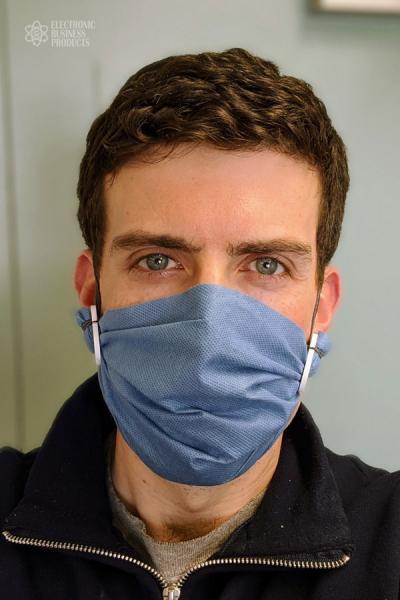

The same can be said for EBP. “Ultimately, with the help of Ricoh, we were able to put thousands of face shields and protective masks in the hands of medical and essential workers across NY state while helping Jeff keep his team employed,” said Liguori. “And we’re not finished. We encourage anyone in need of PPE to place an order with Ithaca College.”

To that end, EBP is helping to facilitate orders through the college. Already, EBP customers have ordered more than 2,000 masks, and more orders are in the pipeline. Ithaca charges $2 per face shield; masks are 75 cents each. The minimal charge offsets the cost of materials while keeping Ithaca’s printing staff employed. For more information or to place an order, please contact Paul Liguori at pliguori@ebp-inc.com or (800) 333-0737, ext. 238.